Compression limiters design guide. Flush nut Installation.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fluid Power Journal

1 COMPRESSION LIMITERS π x Ø2 2 - Ø1 2 ØA ØC ØB L 2.

. The installed Limiter is aligned with the Insert when used to prevent a jack-out condition. Für Wärme- oder Ultraschall-Einbettung. As the audio approaches -18dB with a knee of 3dB the compressor will actually start engaging 15dB earlier knee blurs both ways 15dB before the threshold and 15dB after.

The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component. DESIGN CONSIDERATIONS Table 1 Class Bolt Rating Grade Compression Limiter Series 88 109 88 88 88 109 109 5 5 8 8 CL200 CL220 CL350 CL400 CL460. Installation of Compression Limiters can be done through various technique using heat ultrasonic mold-in or press-in.

Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. Once these mechanical aspects of the engine have been fixed the main variable is fuel octane. Brass Stainless Steel Aluminium.

COMPRESSION LIMITERS x 22 - 12 AP 4 B L A C 1 The Function of a Compression Limiter The primary function of a Compression Limiter is to provide and maintain joint integrity of a plastic assembly. Limiter is compressed between bolts head and mating component. Fundamentally a limiter is a form of heavy compression generally associated with compression with a ratio above 101 if you need a refresher on compression check out our Free Guide to Compression Its for this reason that people are always comparing a limiter vs compressor they perform similar tasks and are based on the same processing.

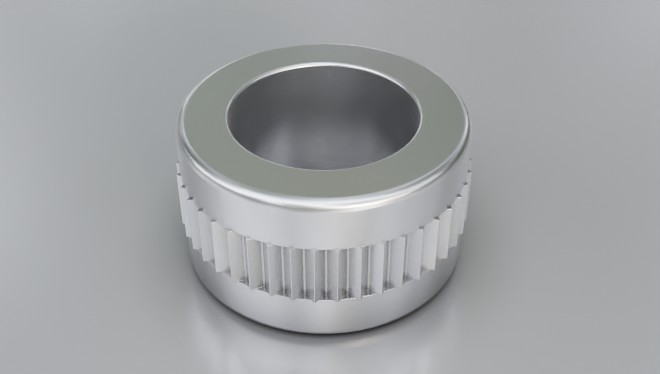

The compression limiter strengthens. Compression limiters are a type of insert or bushing designed to maintain joint integrity of a plastic assembly when tightening bolts or screws. Such features as the specific plastic filler mold design wall thickness and stress.

Installiert nach dem Entformen. SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. 1 COMPRESSION LIMITERS π x Ø2 2 - Ø1 2 ØA ØC ØB L 2.

While the standard tolerance is sufficient to meet most needs verification is recommended. Compression Limiters are rated by the load required to compress the Limiter to a defined safe distance that meets the requirements of. Solid compression limiters provide a strong and reliable defence against the stresses caused by fastener torque.

Included are the specifications for their standard. Correct hole size ensures retention of the Limiter. Cracking and allowing the Compression Limiter to take the fastener load.

Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. While the standard tolerance is sufficient to meet most needs verification is recommended. Compression limiters design guide.

Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series. A properly designed bolted joint must meet the following criteria. The appropriate length and length tolerance is application dependent.

Screws for Plastic to JIS. Compression Limiters Design Guide. Nut installation and tooling.

Higher octane more resistance to detonation and the ability to tolerate more compression. Plas Fix 45 Installation Guide. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

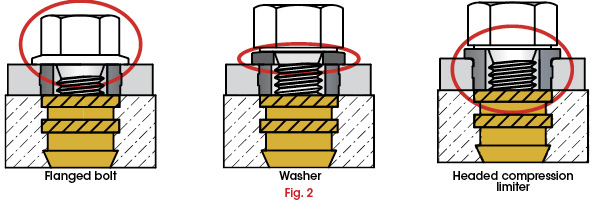

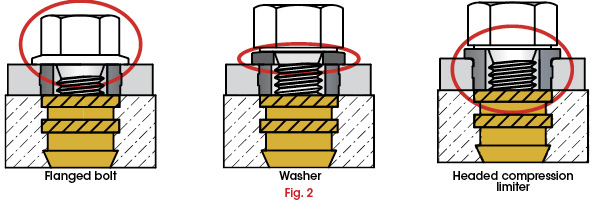

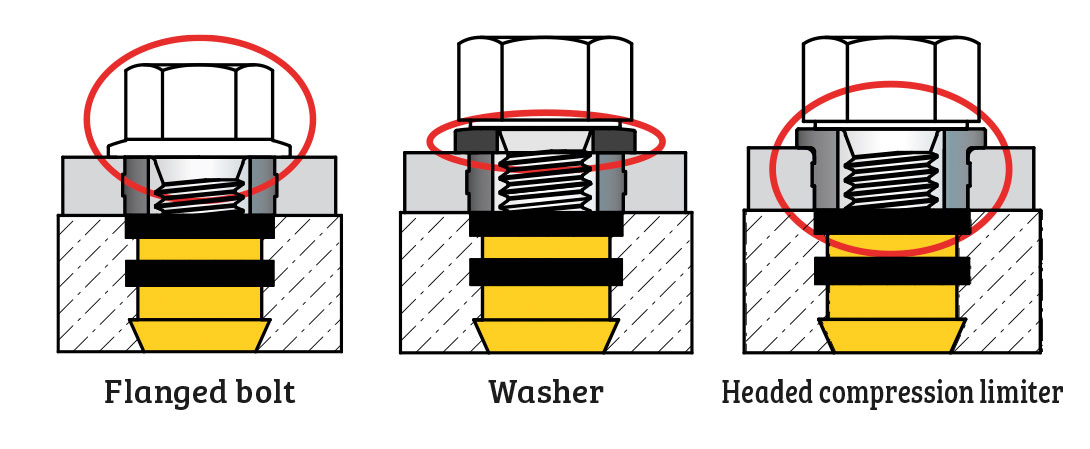

Metric Nuts and Washers. The head of the bolt or washer if one is used should always seat against the Compression Limiter under load. SPIROL Compression Limiters Design guide These include combustion chamber design head material use of combustion chamber coatings etc.

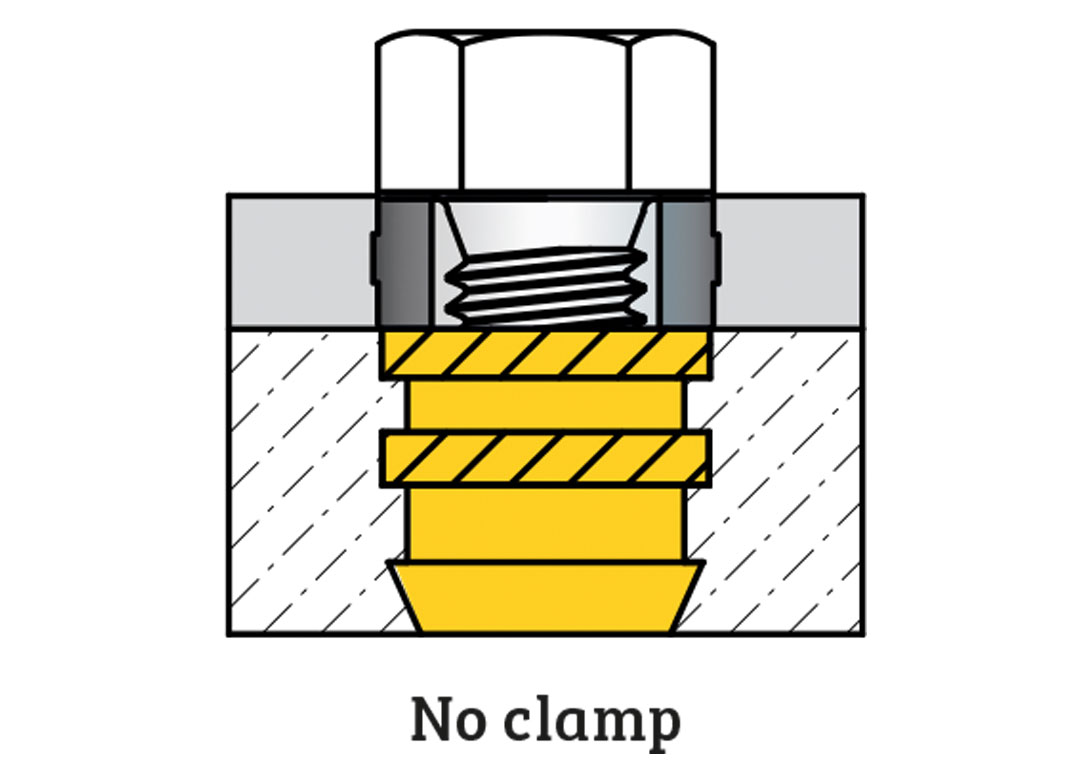

Plastic always exhibits stress and strain relaxation under even modest loads. DESIGN GUIDELINES Allowable Compression of the Plastic Component For most commonly used moulded plastics it is difficult to determine a specific maximum amount that they can be compressed in a short period of time. Volumes and weights are approx.

The appropriate length and length tolerance is application dependent. Compression limiters are made to meet your individual specifications. Host thickness is greater than or equal to the length of the Limiter and able to absorb the clamp load.

The compression limiter strengthens the plastic and withstands the compressive force that is applied when a mating screw is tightened in the assembly. So as your audio hits -195dB youll start to hear more subtle compression and as it moves to -165dB the full ratio will be engaged. Included are the specifications for their standard split seam moulded-in and solid wall designs as well as their brand new oval series.

The compression limiter strengthens the plastic component and withstands the compressive force that is applied when a mating screw is tightened. The integrity of the plastic component is not compromised by the load that is applied. It all starts with our Optimal Application E SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

The integrity of the plastic is not compromised by the load that is applied. Compression Spring Rate - Quality Spring. The appropriate length and length tolerance is application dependent.

Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series. Compression Limiters Design Guide. Compression Limiters are designed to protect the plastic components of an assembly from the compressive loads generated by the tightening of bolts thereby assuring.

2 SPIROLs 5 Step Process for Success When you engage SPIROL as part of your team we will utilize our Log in Upload File. 2 SPIROLs 5 Step Process for Success When you engage SPIROL as part of your team we will utilize our Log in Upload File. The first design is an above-threshold hard-knee compressor with variable ratio thresh-old and gain controls.

They protect plastic parts from damage due to compression by limiting the force that gets applied to the plastic by the assembly fasteners. While the standard tolerance is sufficient to meet most needs verification is recommended. This will prevent deterioration of the bolted joint resulting from diminished clamping load due to plastic creep.

1 Prepare holes with a taper of 1. Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly. Stud installation and tooling.

There are too many variables involved to make a specific calculation. Headed Compression Limiters are only available as solid components because of the tolerances required for proper Compression Limiter operation. Nach DIN 16983 früher DIN 2093 Aus Edelstahl.

The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component. The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component.

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

Compression Limiters And Compression Limiter Assemblies Psm Celada Fasteners

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

Webinar Threaded Inserts And Compression Limiters For Plastic Assemblies Youtube

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly 2015 11 04 Assembly Magazine Assembly

Tr Launches Range Of Compression Limiters Fastener Fixing Magazine

0 comments

Post a Comment